About "DAILY F&B STORY"

"DAILY F&B STORY" provides coffee roasting services on demand, combining modern technology and a team of experienced roasters. We constantly optimize the process, advise and adjust the roasting profile to ensure your products meet the highest quality standards, while meeting the diverse tastes of the market.

With coffee roasting services, "DAILY F&B STORY" is committed to providing a professional process, fully meeting the criteria you set, providing optimal support to make your products stand out in the market. For you - coffee traders:

• Do you own a private brand coffee chain?

• Are you a commercial intermediary partner or are exporting coffee?

• Do you need an optimal roasting solution and superior quality?

"DAILY F&B STORY" is the ideal partner for you. Let us accompany and support you from consulting, roasting profile design to product completion. You can focus on your brand development strategy with peace of mind, while "DAILY F&B STORY" ensures the perfect quality of the finished product as expected.

"DAILY F&B STORY"

Superior quality, professional service, accompanying your success.

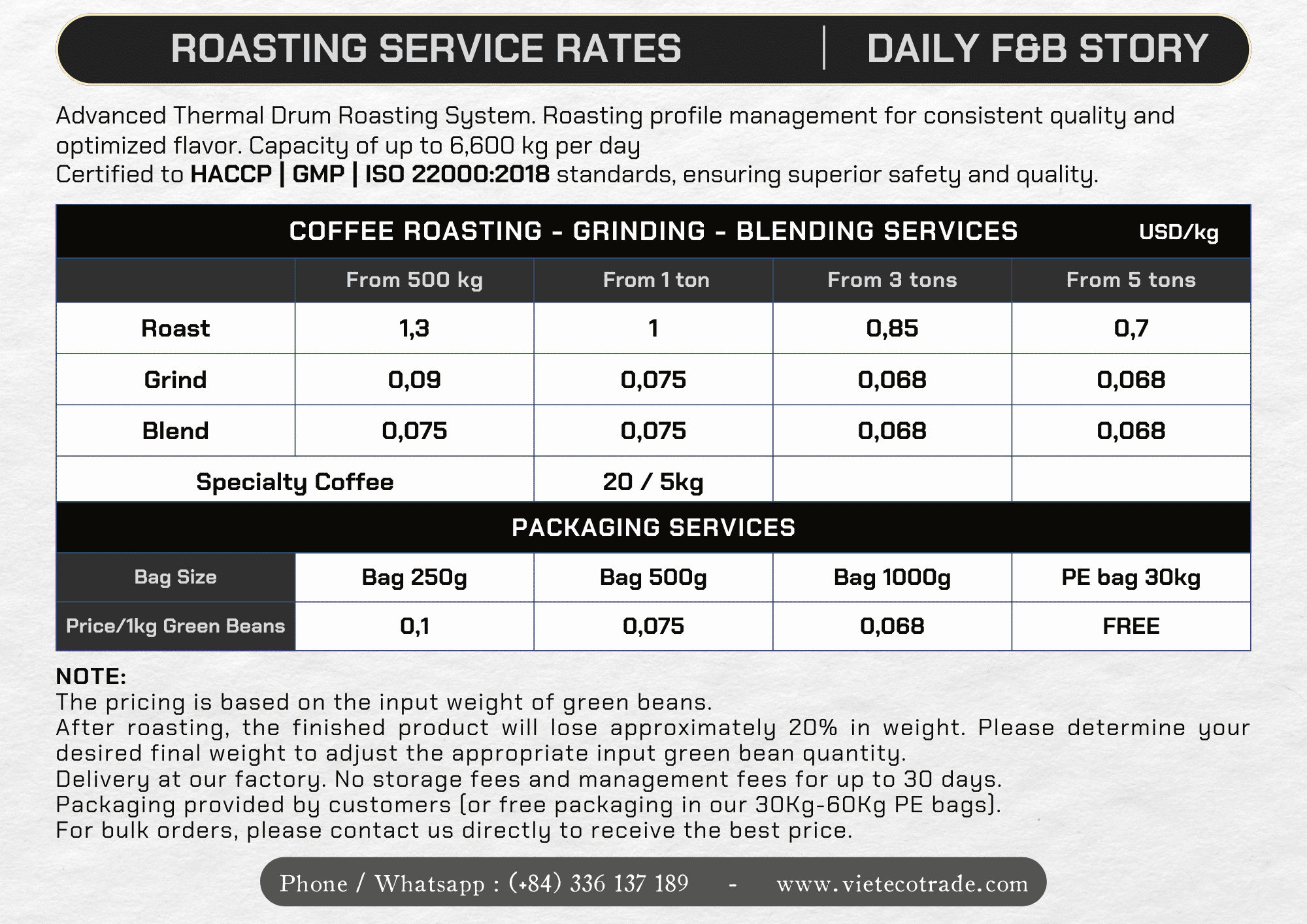

Unit price is calculated by input kilogram of green coffee beans. After roasting, the finished product will lose about 20%. Customers determine the desired finished product weight, to balance the appropriate input green bean weight.

Example 1: You need 600kg of ground coffee and the packaging is 1kg/bag (bag provided by you).

✅ The required input green bean mass is 720kg. Consult the price list to determine the achieved price.

Processing cost = 720kg x ( 1,3 + 0,09 + 0,068 )

When the input green bean mass reaches “From 500kg”:

1,3 : processing cost per 1kg.

0,09 : milling cost.

0,068 : packaging processing cost according to 1kg bag classification.

Example 2: You need 1 ton of finished beans mixed with 60% Robusta and 40% Arabica. Packaging specification: 500g bag (bag provided by customer).

✅ So the total input green coffee beans needed is 1250kg (including 750kg robusta beans and 500kg arabica beans).

Processing cost = 1250kg x ( 1 + 0,075 + 0,075 )

When the input green bean mass reaches “From 1 ton”:

1 : processing cost per 1kg.

0,075 : mixing cost.

0,075 : packaging processing cost according to 500g bag classification.

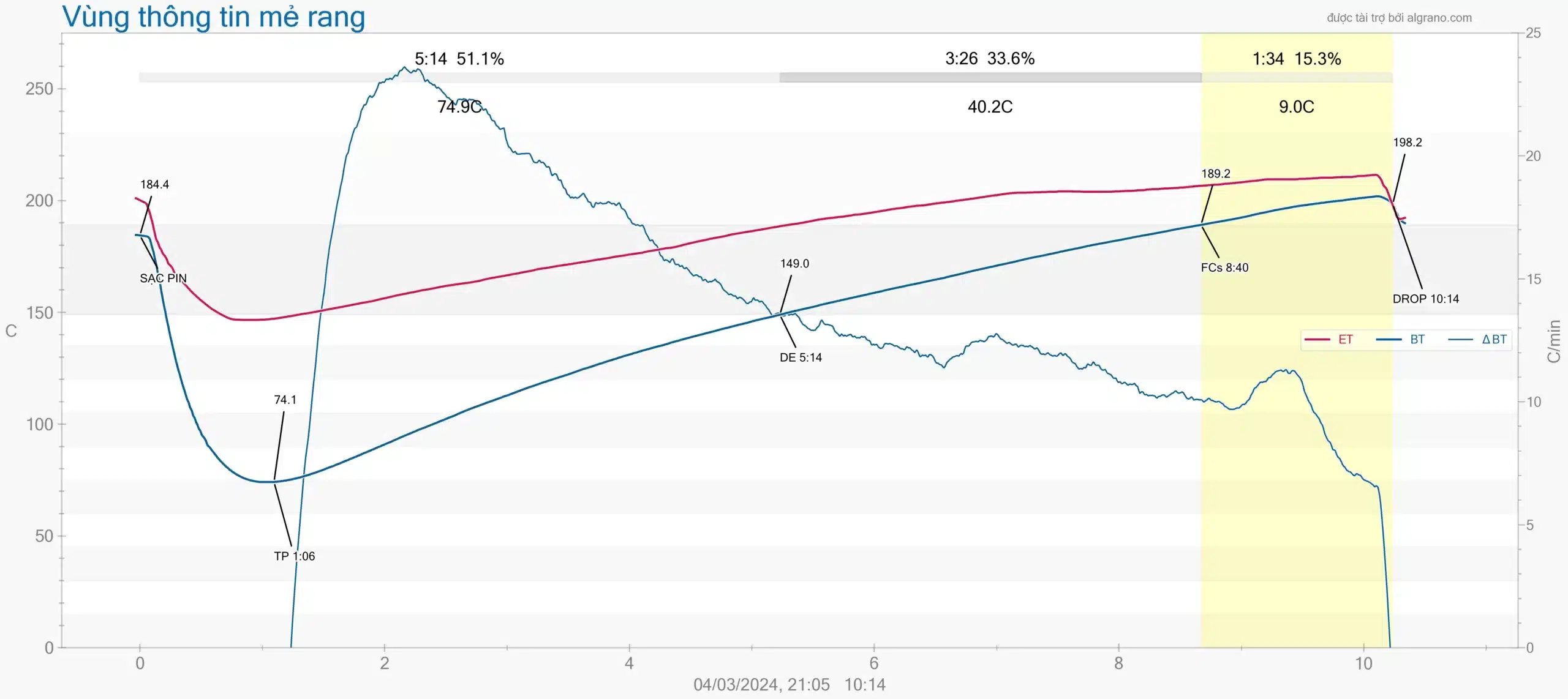

* Roasting by Profile

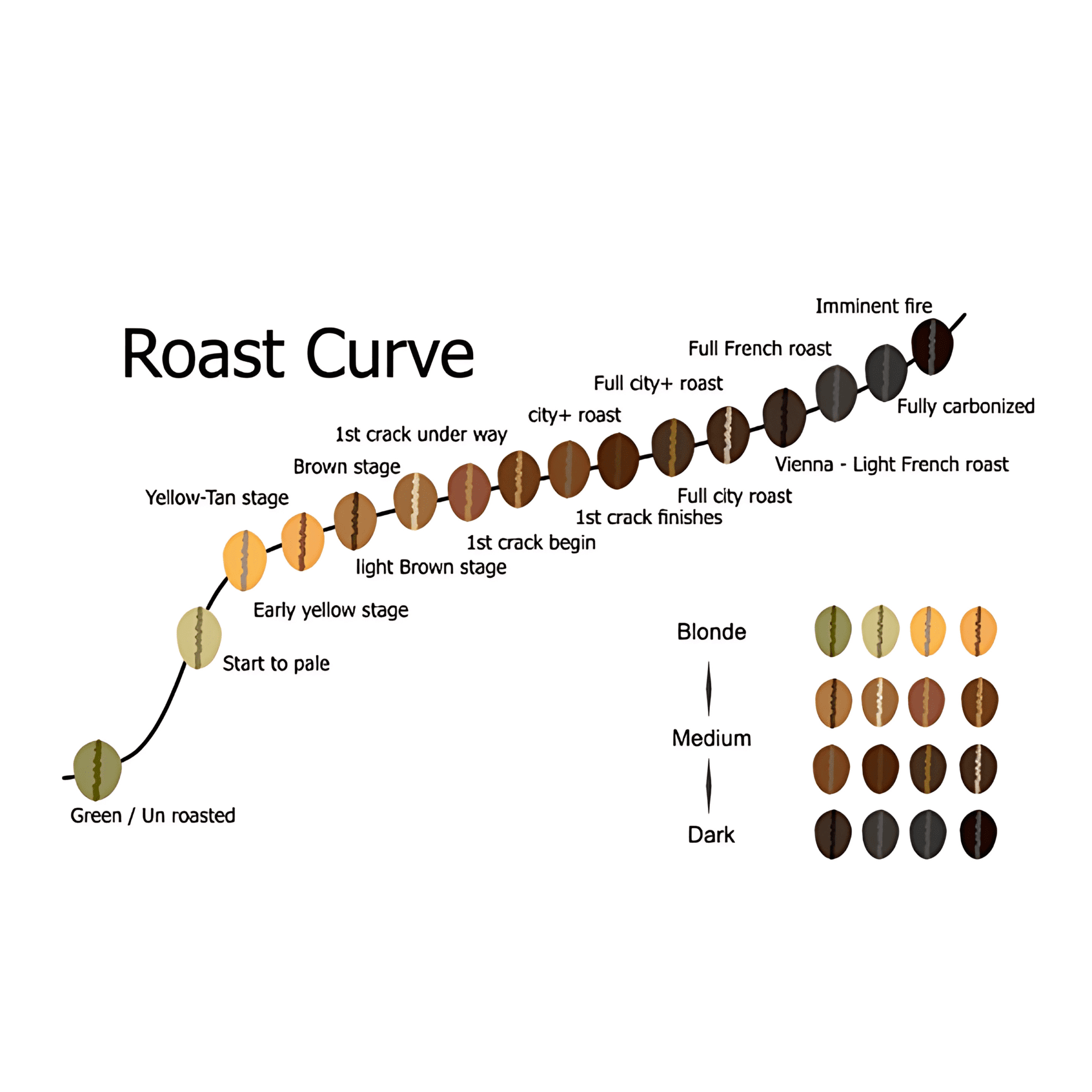

Each roasting batch is closely monitored through the roasting profile chart, which can be adjusted to suit your taste, and the file is saved to ensure stability for subsequent roastings.

Ensures the coffee beans are evenly cooked, not bitter, not burnt on the edges, and retain the full rich flavor.

* Production Capacity

We operate four state-of-the-art coffee roasting machines, ensuring a production capacity of up to 6,600 kg per day. Utilizing an advanced Thermal Drum roasting system combined with multi-layer dust filtration technology, we guarantee the complete removal of impurities, husks, and defective beans, delivering consistent and optimal roasting quality.

PRESTIGIOUS AND QUALITY COFFEE ROASTING PARTNER

CUPPING COFFEE EVALUATES THE QUALITY OF SAMPLE COFFEE

MODERN ROASTING SYSTEM

OPTIMIZE COSTS FOR PARTNERS

DIVERSE ROASTING PROFILE, ON DEMAND

ROASTING PROCESS

Operating Procedure

01 Customers Send Us Requests

• Customer information (name, phone number, email, company, etc.)

• Products to be processed: product type, specifications, expected order quantity, etc.

• Customer distribution market: domestic, international.

02 Receive Requests & Consult

We receive your request via Email, Messenger, or WhatsApp. Our consulting team will contact you to discuss details, send a quote with terms and conditions.

03 Sign The Contract & Start Roasting

After the customer chooses the coffee model and packaging (OEM/ODM) that suits their needs, we will sign a contract with the customer and receive a deposit to start processing.

-> Case 1: The customer already has green coffee.

• Receive green coffee from the customer, roast according to the agreed profile.

• Pack the product according to the agreed requirements.

• The customer completes payment after checking the product.

• Hand over the goods to the exporting unit at "F&B Story"'s factory.

-> Case 2: The customer does not have green coffee.

• Introduce and connect customers with suppliers of high-quality green coffee at competitive prices.

04 Packaging & Delivery

Packed with your brand or ours carefully. Then delivered on time.

** Commit

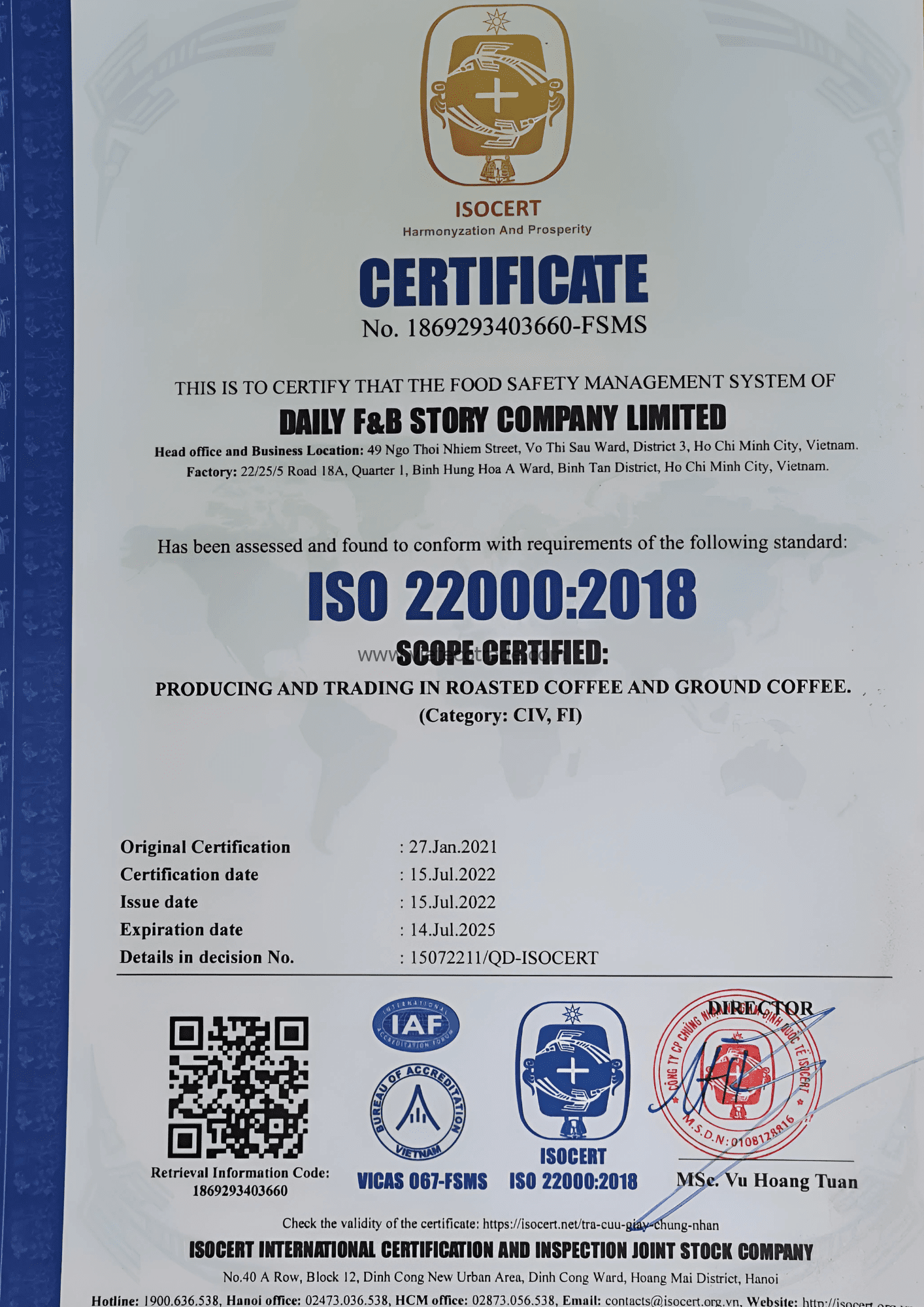

• Standard assurance: All processed coffee meets international standards such as ISO, HACCP, or specific requirements of the export market.

• Flexible support: Providing flexible services, from roasting to supporting connections with reputable and professional suppliers of green coffee, packaging, etc.

• Time & payment: Committed to on-time delivery and clear payment terms for the convenience of both parties.

PARTNERS UNITS

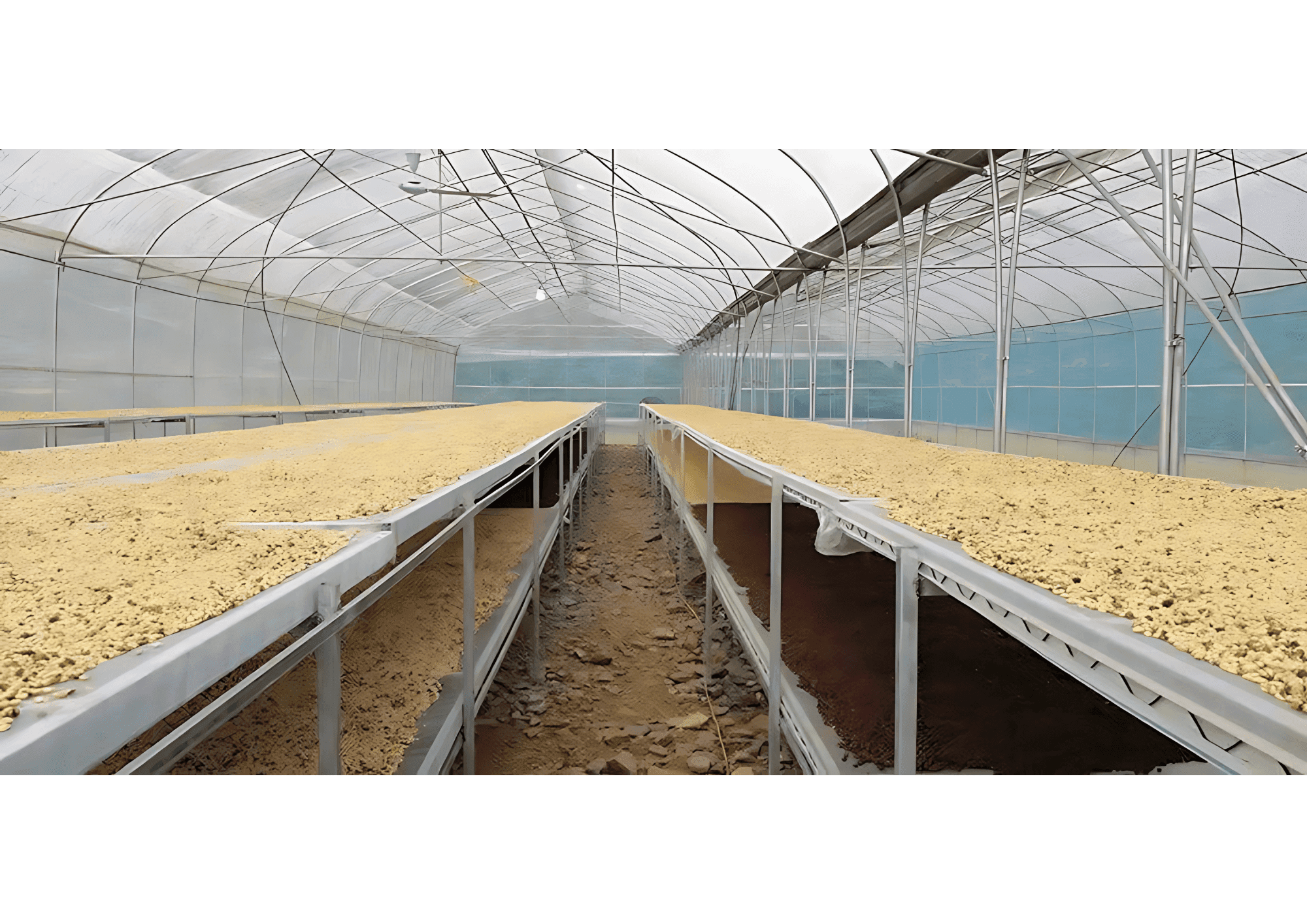

COFFEE FARM

GREEN WAREHOUSE

ROASTING PROCESSING PARTNERS

International Services

International Standards Certifications